I do not remember learning to drive. This is true. I do not remember anyone telling me to push in the clutch and now shift this way to go forward or that way to go backward. But I do remember having a hard time seeing over the dashboard when I did drive. Now mind you, I was not driving out on the highway at that age. I was just doing as I was told. If dad wanted the truck moved, I moved it. My only memory of an accident was when I once smashed the left front fender on the pickup. We were at a windmill site and he wanted the pickup moved from where it was. I started it up and backed out while cutting the wheels to the right. I did not know that there was a fence post right next to the left front fender. He heard the crunch, came over to view the damage and gnashed his teeth the way he did when he was angry. I did not know the fence post was there because I could not see it from the seat of the truck with my right foot all the way down there on the gas pedal. There was no fence either - just a lonely fence post sticking up there which made the rest of my day miserable.

But I was the driver, all right. I drove the truck to pull sucker rods and pipe. I will explain first the process of pulling sucker rods: Sucker rods are (or were) made of wood, twenty feet long and had steel couplings on the end and held onto the rod with copper rivets. There is a special tool called a rod wrench which fits onto the square shank under the shoulder of the coupling. The rod wrench works with the rod elevator which also fits the coupling, can be used as a wrench, but with a loop which swings up to connect to the cable hook which pulls the rod up. With the elevator in place, the driver backs up the truck to pull the string of rods up until the next coupling is above the top of the pipe. Another elevator is slipped onto the lower coupling and the truck moves forward to let the weight down onto the pipe. The rod wrench is then used with the elevator to uncouple the joint (break the joint) and the worker under the tower then takes the end of the rod and leads it out of the tower as it comes down (laying them down).

But before all this begins, the cable has to be rigged. One end is tied to the front of the truck and the other has the traveling hook. It goes through a snap block chained to one leg of the tower and another block chained near the top of the tower. The driver backs up the truck to raise the load and runs forward to lower it - there is no mechanical advantage. The range of motion of the truck is about twenty feet.

All rod pulling jobs are done with winch trucks these days and it was a winch truck which replaced my dad's rig when he sold out his business in the 1980's. But meanwhile, I was the driver and it was my responsibility to make things work by my driving skills. When I was very young, I saw my dad do the driving while his helper did the work under the tower. When I became the helper, dad coached me in some of the fine points as I worked into it. Toward the end of my rod pulling career, he expected perfection and I would hear it from him if my performance was anything less. My only perfect performance was probably the time I got to use a tractor instead of the truck. There was one rancher who had a tractor which he lent to us for pulling. It was so powerful and smooth; I could make each move as precisely as if I were operating a winch. Now if you reread the second and third paragraphs above, you will get an idea of what rod pulling is like when everything is going well. But now, I will have to describe for you all the things that can go wrong:

At the very beginning, the first pull is crucial. I have the truck in reverse and back up to just tighten the line. Now, dad can grab the line where it moves up the tower and lean over with it. Experience will tell if the full weight is coming up. Less can mean that the rod might be broken and we are facing a pipe pulling job. More could mean other kinds of trouble. I now have to judge how much to rev the engine for the initial pull. If I underestimate, the engine will stall before the first joint is pulled out and I have to ease it all down with the brake and try again. At the same time, too hard a jerk can break the rod or something else. To complicate matters, for the first couple of feet, the valve is still in the cylinder and I may be picking up a column of water as well as the rods. So, with all of this in mind, I make the first pull as strong as necessary but as smooth as possible. Sometimes it would take more than a few tries. There was another thing that could go wrong and was guaranteed to cause my dad to have a terrible fit of rage. Not very often, but sometimes, when the valve comes out of the cylinder, the leathers on the valve would turn backwards and jam the valve in the pipe. There is nothing to do here but to pull the pipe. Avoiding pipe pulling jobs was one of our main intentions.

While backing up, I have to maintain my inertia which implies a minimal speed. I am concentrating on the top of the pipe and as soon as the joint makes its appearance, I stomp the clutch and then an instant afterward, the brake. Bam bam! Meanwhile, on the way up, I am also watching the top to make sure that the hook does not hit the block at the top. If it does, then something will have to give and the most likely consequence is that the string of rods will fall. Sometimes it is close, especially on pipe pulling jobs where one never knows how long the joint of pipe will be. Therefore, there is a short distance where I must hit the brake. Sometimes, after making many back and forth trips, the surface where the braking happens gets ground up into a powder making the truck actually slide.

With the joint above the top of the pipe, the elevator goes on and dad raps the joint several times with a ball peen hammer to loosen it up and then uses the rod wrench to break the joint. At this point, I must make sure that there is enough slack in the cable so that the elevator at the top can swivel but not so much that the elevator might fall off. If it falls, it will hit my dad on the head. With the joint apart, he walks out away from the tower with the bottom end of the rod as I drive forward to lay the rod down. This part sounds simple enough but I have to be very gentle because the rod has no lateral strength and the weight of the elevator can snap the rod as the rod lands on a pile of rods. I remember making that mistake once and of course, my boss was not pleased since he would have to make a replacement or repair. Also, as the rod lies down, dad has to make sure that the elevator is turned so that the gap remains closed holding the rod in place - otherwise, the rod falls out. The hook transfers to the other elevator and I am ready to back up again.

When we pulled the pipe, we had a traveling pulley with the hook on it so that there was a mechanical advantage of two. On one occasion, I remember that this was not enough and we rigged up a ground line with another pulley to make a mechanical advantage of four. We had pipe elevators for each common size of pipe and chain wrenches for breaking the joints. Pipe jobs were of different types: pipe only, pipe with rods inside (a case of a broken rod), pipe full of water, and pipe with rods and water inside. When the pipe is full of water, of course, it is a whole lot heavier. When the rods are in the pipe, then you have to break the pipe joint and then lift the pipe up high enough to find a rod joint to take apart. These last jobs were the worst and any trip out of the hole with water inside means that each joint sprays its contents of water when disconnected. Water sprays up into your face and eventually the work area is a mud hole. Those jobs were truly miserable but at least you were kept cool because you were totally soaked.

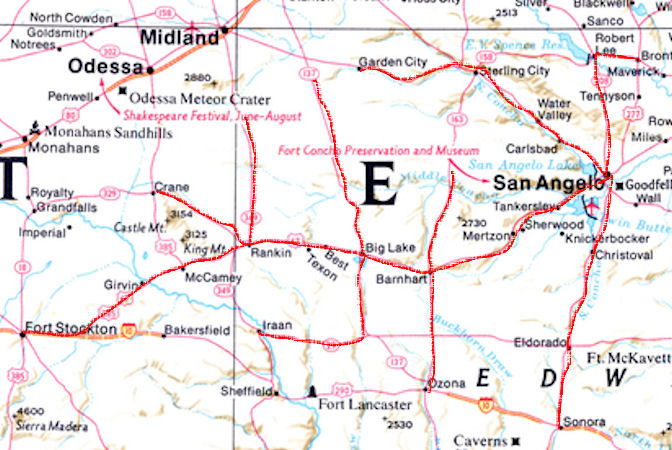

I was not always the driver. On one particularly hot day, dad decided that he wanted me to break the joints on a rod job near Big Lake. It was a deep well, probably 400 feet deep, and that would be at least 20 rods. He would get mad at me if I worked too slowly and that day he was really pushing hard. The joints were tough but I beat each one between the ball peen hammer and a sledge hammer and then I had to put a cheater arm on the rod wrench and pull with all my strength before I could get them to come loose. By the time we got that string out of the hole, I was delirious. I remember that we broke for lunch, ate a little something and then we had a can of sliced peaches. The last thing that I remembered, I drank the sweet juice from the bottom of the peach can. I woke up later lying back against my bed roll. I had passed out and dad had left me to rest. I wonder if he was testing me that day and I wonder if I passed the test.

There was a little combination gas station and liquor store on the south side of the highway in downtown Big Lake - a tiny stucco building. The proprietor was a small foul mouthed man who was probably an alcoholic although I did not know the meaning of that word in those days. It was our Big Lake headquarters. If we were spending the night in Big Lake, we would sleep in a little shack in back of the place which had two small beds, not a fan to relieve the heat, and no screens on the windows to inhibit the passage of mosquitoes. It was a miserable place but dad had some arrangement with George (maybe that was his name) which allowed us to sleep there.

In the time between supper and bed time, we would have a soft drink, enjoy the lower nighttime temperature and talk to George while he waited on the occasional gasoline or whiskey customer. I came in the back door one night and dad was talking to George. They were around the corner from me and they were not aware of my presence. I overheard my dad say that "He is the best driver I ever had". As I listened, I learned that he was talking about doing rod jobs. Now Peck Young went through a lot of helpers in his career and he drove many of them off by his cruelly hard work and his explosive temper. As I listened, I was amazed to learn that he was talking about me.

I was about 17 years old and I had never heard my father say anything complementary of my work. His fierce temper was usually directed toward inanimate things such as a wrench which falls off of the tower or some object that breaks causing trouble and delay. But if you are in his presence when the temper flares, you feel like you are one of the cursed objects, the cause and the essence of his misery. Working with him, there was the constant dread that something would go wrong and very seldom was there the pleasure of accomplishment. And he never said to me: "nice job!", or "that was good driving!" - Nothing positive at all. It was not his nature.

OK, so I was the best driver he ever had. I was complimented but lost something deep inside me in the process. I slipped back out the back door of that dreary building in that dreary place so as not to break the propriety of the moment.